9

FACTORIES / OFFICES

+ 900

EMPLOYEES

5

BUSINESS LINES

7

SECTORS

+ 500

CUSTOMERS

10% EBITDA

ANNUAL EVOLUTION

30-35%

R + D

Mission

Alfran is characterised by always seeking Excellence in our Products and Services, which are Customised, in order to be the Industrial Partner of reference for our Clients and to generate Value.

Vision

Our Vision is to Protect the Core of our Clients’ Industry, so that they save Time and can Produce More and Better.

Values

9

FACTORIES / OFFICES

+ 900

EMPLOYEES

5

BUSINESS LINES

7

SECTORS

+ 500

CUSTOMERS

10% EBITDA

ANNUAL EVOLUTION

30-35%

R + D

Certified quality since 1994

Alfran guarantees quality in all its projects, offering coordinated and integrated services, from engineering of solutions and product manufacturing, to on-site assembly and final delivery of the equipment.

We have extensive experience in the following industrial sectors and their respective

equipment.

We are a reference in the cement industry worldwide specialized in high performance refractory castables

Alfran provides products and services for power generation industries such as coal power, nuclear, combined cycles, cogeneration, incineration, biomass and solar plants.

Over the past 50 years, Alfran has become a leading supplier of products and services to the Iron & Steel industry.

Alfran designs, manufactures, supplies and installs a wide variety of materials and solutions for plant applications in the Oil&Gas industry.

Alfran designs, manufactures, supplies and installs a wide variety of materials and solutions for non ferrous metals industries, such as aluminum and copper.

Alfran provides high value-added products and installation services, with strong commercial alliances in the supply of materials within the glass sector.

Alfran considers PREVENTION a VALUE integrated into all its activities and business lines, in technical procedures, in the organization of work and the hierarchical line at all its levels, being a fundamental part of the strategy and goals of GRUPO ALDOMER.

Our greatest difference

We create more value through our innovation strategy, with ambitious targets and measurable results.

Collaborative projectss

Engineering of multilayer coatings for different industrial processes

Design of refractory materials

Energy Efficiency and Sustainability

We minimise both the consumption of virgin raw materials and waste generation, closing the economic and ecological resource loops.

Our company is based on continuous improvement +digitalization, to adapt to a constantly changing world and to achieve our goal of competitiveness + excellence.

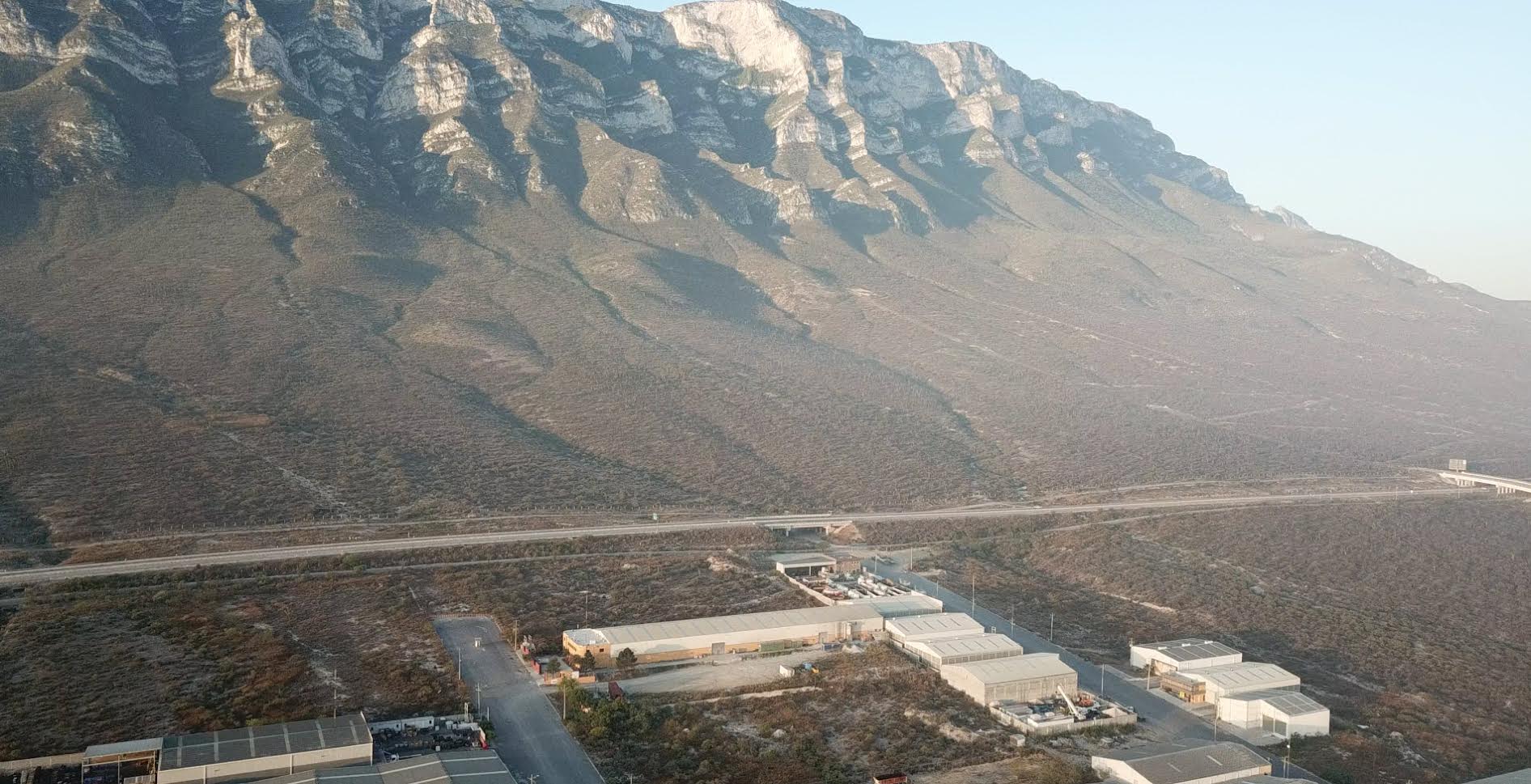

ALFRAN designs, manufactures and installs a wide variety of refractories for turnkey projects in new production lines and maintenance work.

We have over 85 years of experience as a leading company on the refractory field. We protect the core of any industry requiring linings designed to withstand high temperatures and physical & chemical attacks.

Supply and installation of thermal insulation for heat and cold in boilers, turbines, tanks, equipment and pipes, for all types of industries.

These works are carried out in refineries, petrochemical plants, gas plants, nuclear plants, chemical and pharmaceutical industries,

cement factories, cellulose and sugar mills, among others.

ALFRAN offers a comprehensive passive fire protection service for all types of constructions, particularly for hydrocarbon fires in the oil and gas sector.

These solutions include advice on passive fire protection and current regulations, design and engineering of solutions, supply of tested and approved construction systems, and on-site installation.

Alfran is a manufacturer of FIREIND cementitious mortar, a lightweight mortar with high mechanical strength, resistant to external weather conditions. It doesn’t contain asbestos and complies with all current safety requirements.

Turnkey Integrated Service Contract, which included the Engineering, Supply, Installation and Drying of refractory material for CEMEX‘s plant in Maceo, Colombia. The scope included the Preheater Tower, Tertiary Air Duct, Clinker Cooler and other auxiliary equipment, totalling more than 1,420 MT of materials. The project was executed on schedule and to the full satisfaction of the client.

In 2020 Alfran was awarded the contract for the supply and application of fireproofing and thermal insulation materials for the Borstar Bay3 project. This project is a milestone in the region as it involves the construction of a new 625,000 tonne/year modular High Density Ethylene (HDPE) production plant.

The fireproofing work involved the application of more than 7,000 m2 of intumescent epoxy material in 13 of the 27 modules that make up the plant. This task could be carried out in a timely manner thanks to the excellent qualifications of Alfran’s personnel, a fact for which the client congratulated us.

On the other hand, the Thermal Insulation works were carried out on all the piping of the 27 modules and on 41 process equipment. The materials required included the application of rock wool, PIR and cellular glass, among others. All these components were installed in accordance with the highest quality standards in the sector, such as the C.I.N.I. standard (International Standard for Industrial Insulation).

Alfran carried out the repair of the reheating furnace at the GERDAU steel plant in Sahagún, Hidalgo (Mexico). Specifically, the execution of this project consisted of the repair of the skids in the equalisation zone and the heating zone.

In this project, our Drytech 70 concrete was used, both in its version for installation by vibrocasting and in its version for application by Shotcrete Alfranjet technology, in the front walls, exit doors and vault blocks. Our TIX product range, TIX 80 and TIX 60, was used for the skids.

In total more than 50 tonnes of high quality concrete were installed by Alfran in this project.

Alfran carried out the complete replacement of the refractory castables of JATCO’s aluminium Reverberatory Furnace No. 3 at the Aguascalientes (Mexico) facility. In a record time of 25 days, Alfran supplied and installed materials specially recommended for this equipment, such as Drytech 85 AL, Drytech 85, TIX 40 and our insulating concretes from the LITE range. In addition, 25 tonnes of solidified aluminium were removed from the furnace.

The client was delighted with the good work of our team, both in the execution of the installation and in health and safety, which has positioned us at the forefront of the aluminium sector throughout the American continent.